Press Release

Published 04/2016

NOJA Power Smart Grid Automation Software turning Engineering Vision into Reality

It’s amazing what utilities can achieve when they provide engineers with the right tools to achieve their vision. Introducing the latest addition to the suite of functionality in the NOJA Power RC-10, Smart Grid Automation – Distributed PLC for advanced custom logic.

Implementing distribution system automation is a considerable challenge which faces utilities the world over. The benefits of centralised distribution automation are well documented, with cost savings, efficiency and risk mitigation at the forefront. The challenges however lie in the generalised inability for network assets to work together. How do utilities manage to tie together multiple network assets, from multiple manufacturers and multiple locations into a single cohesive standard?

From transformers to reclosers, each individual network asset has its own unique personality. No matter how clear a tender specification may be, the end product provided to the SCADA interface for centralised automation will always inevitably be different. For decades, the SCADA and standards engineers within the utility organisation have tried to beat each manufacturer’s relay into a standard cookie cutter shape which would enable the utility to integrate all network assets into a single, efficient and cohesive machine, but this would always come at a cost of forgoing the forward thinking of the manufacturer who wishes to accomplish something new in their product.

There must be a better way to adapt multiple devices and their sensor data to accomplish automation. Fundamentally, all protection relays behaviours are based on reading and writing to an evolving database of sensor information. The recloser behaviour, and ultimately the recloser functionality is based on the algorithms and capabilities of that recloser to respond to these inputs. But what if the algorithms were open to modification? What if the data was presented in such a way that the engineer can tailor all their functionality to meet their requirements? What if an engineer could connect multiple reclosers on the same IP network and share information between controllers?

The truth is there has been a standard in development for years to attempt to bridge the gap between devices with their own smarts to allow multiple units to all speak the same language. That language is IEC61499. Today for the very first time in recloser standards, this protocol is available in the most advanced recloser controller available today, the NOJA Power RC-10 Recloser Control.

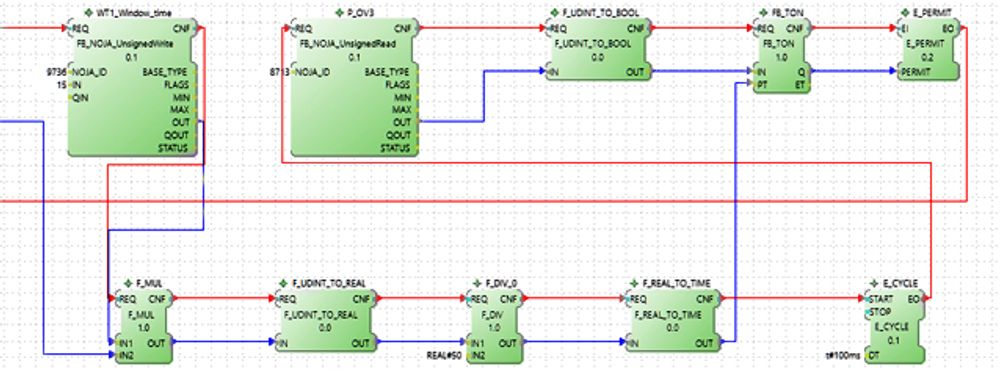

Dubbed Smart Grid Automation by NOJA Power, this recloser-optimised adaptation of IEC61499 is the diamond tipped blade where simple Logic won’t cut it anymore. With full access granted to all read and write database points in the recloser controller, engineers and operators have complete configurability of the functionality in the controller. After trial by Australian utility users to accomplish their network automation configurations the feedback has been incredible.

“We can do absolutely everything we wanted to achieve with Smart Grid Automation (SGA), this has never happened before with any relay manufacturer, we could not be any happier”.

Smart Grid Automation runs in parallel with the standard functionality in the RC-10 controller, allowing engineers to embrace the best of the standard protection and metering capabilities offered by the NOJA Power RC-10 controller whilst tailoring additional custom SCADA points, interlocks and automation scheme solutions to fit with any network requirements.

The possibilities of customisation are limited only by the imagination of the engineers using them. By utilising an IP based network, it is possible to share information between NOJA Power RC-10s. This unlocks capabilities with distributed application automation, such as an upstream recloser that could detect brownouts on a feeder, then progressively shed the load at each downstream recloser, without any intervention from operators.

Practically speaking, with immediate access to all sensor data and database points within the controller, applications can be developed and customised to equip recloser testing staff with an interface with real time feedback on entire protection schemes within a controller. This capability alone would justify the use of SGA, but through intelligent use of this information and algorithm design the protection engineer has a tool which can be used to solve any functionality request.

NOJA Power’s RC-10 controller is clearly the most advanced recloser controller available on the market today. With the advent of Smart Grid Automation IEC61499, the world’s most intelligent controller has gone to college. If the application requires a novel solution, adaptive protection or an interlocking requirement, the NOJA Power RC-10 is the equipment to achieve your vision.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →