Technical Article

Published 09/2023

How the NOJA Power VISI-SWITCH® provides Isolation

Load Break Switches are fundamental equipment for the electricity distribution network. Switches are designed to operate on normal operating load currents, and when in the open position, provide a degree of insulation between live network and the isolated section of the line.

Hence the name, a “Load Break Switch” – a switch that can break currents up to the normal load current.

Today, the two most common designs of Load Break Switches use either a set of contacts with open Air insulation, or enclosed contacts in an SF6 tank.

Air Break Switches

Air break switches are a type of Load Break switch, that uses large clearances in air between the open contacts to provide electrical isolation. The advantages of this design is its cheap upfront cost, but the exposure of the contacts to the environment leads to a high maintenance cost and reliability issues. Utilities often de-energise lines to service air break switches, to allow them to operate again at their rated capacity. Equally, the exposed contacts introduces a risk of wildlife bridging the isolation gap when in the open position.

SF6 Load Break Switches

SF6 enclosed load break switches solve the exposed contact issue and reduce maintenance, but at the cost of requiring highly polluting SF6 gas as an insulating medium. 1 kg of SF6 has the greenhouse equivalent of over 23,000 kg of carbon dioxide, and it persists for 3200 years in the atmosphere. SF6 gas devices require maintenance and top-up of leaked gas, along with reclamation of the SF6 gas at the end of life during decommissioning. Lastly, the point of isolation is not visible within the SF6 tank enclosure. Operators must rely on the external position indication of the switch as the only clear indicator of the switchgear position.

The NOJA Power VISI-SWITCH®

The NOJA Power VISI-SWITCH® combines the advantages of both Air break switches and SF6 Load break switches, without the need for polluting SF6 gas.

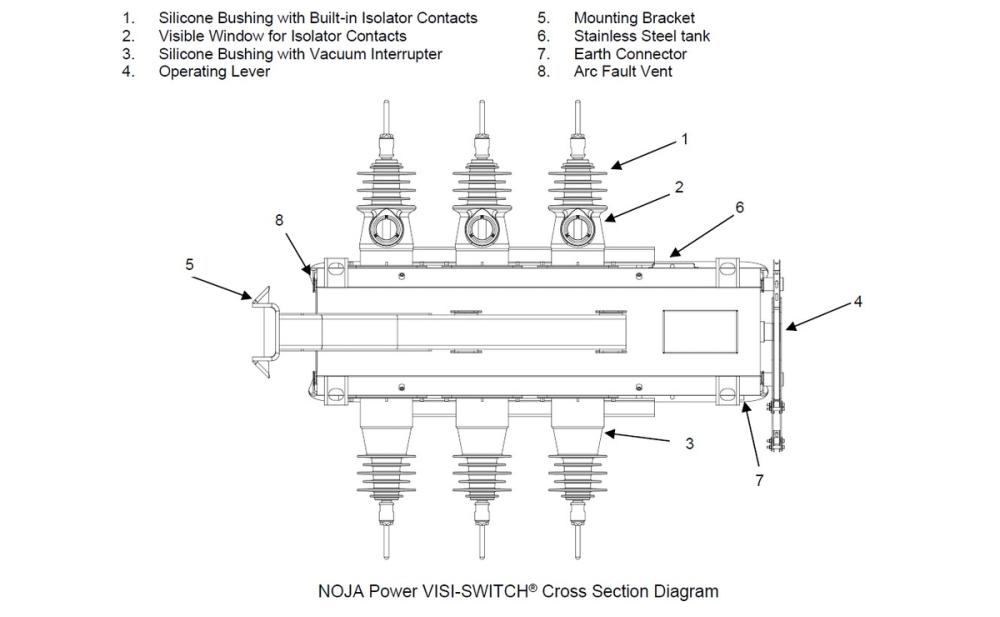

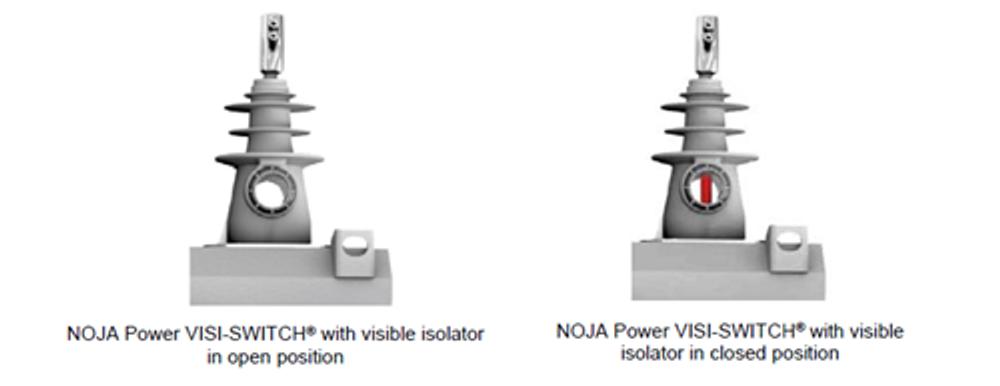

A NOJA Power VISI-SWITCH® encloses a Vacuum Interrupter and an off-load isolator in a single closed tank assembly. When an operator actuates the device from closed to open, the operating lever charges a spring mechanism. When sufficient energy is stored, the mechanism releases. The internal sequencing mechanism system first opens the vacuum interrupter to break the current, before retracting the isolator into the device. The isolator itself is an air gap, which alone provides the required Basic Insulation Level, or BIL, but this air gap is enclosed in the NOJA Power VISI-SWITCH® tank with a special viewing window.

Operators can look through the viewing window and physically confirm that the isolation gap is present. This isolation gap alone provides sufficient BIL to meet standards.

When closing the NOJA Power VISI-SWITCH®, the operator handle charges the same set of springs, but the internal sequencing mechanism reverses the order of operations. Once sufficient charge for a close is stored, the mechanism releases, first closing the isolator, before closing the Vacuum Interrupter to complete the circuit.

This topology ensures that the Vacuum Interrupter is the point of electrical interruption.

“The NOJA Power VISI-SWITCH® is the ideal alternative to both an air break switch and an SF6 load break switch,” says NOJA Power Group Managing Director Neil O'Sullivan.

“The air break switch provides visual break isolation, the SF6 switch provides enclosed contact reliability. The NOJA Power VISI-SWITCH® provides the operators with visual break isolation and increased safety with all the reliability benefits of an enclosed switch eliminating the use of SF6 gas.”

For more information, visit www.nojapower.com.au or contact your local NOJA Power Distributor.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →