Technical Article

Published 11/2023

Four Ways Engineers Install NOJA Power OSM Reclosers

Installation quality matters, and quality comes from consistency. So how do engineering teams design Recloser installation arrangements to meet the varied scenarios of the distribution network?

By using the various standard NOJA Power mounting brackets.

Here we explore 4 different OSM Recloser mounting methods, with some advantages and disadvantages.

1. The Standard OSM Recloser Mounting Arrangement

By far the most common method of installing the OSM Recloser is NOJA Power’s standard mounting bracket. Designated the OMB-18, the standard Pole Mount bracket is used for timber pole installations using two M20 bolts. The recloser itself is attached to the bracket using four supplied M12 bolts with split ring and flat washers.

The standard OSM Recloser mounting bracket is the most cost-effective option for timber pole mounting, as the compact design simplifies shipping of the full product assembly. There are other mounting bracket options which reduce on-site works, which can save greater capex where installation costs are high but shipping costs are relatively lower.

The standard OSM Recloser mounting bracket is often paired with the VTMB-10 Voltage Transformer Mounting Bracket (as pictured), allowing the auxiliary supply transformer to be mounted on the opposite side of the pole but sharing the same M20 bolt.

Lastly, the standard mounting bracket can also be supplied with a C-clamp kit, removing the need for bolts through the pole. There are various options available depending on the pole diameter – so it’s best to discuss these with your NOJA Power representative to get the right fit for your application.

2. The Combined Mounting Bracket

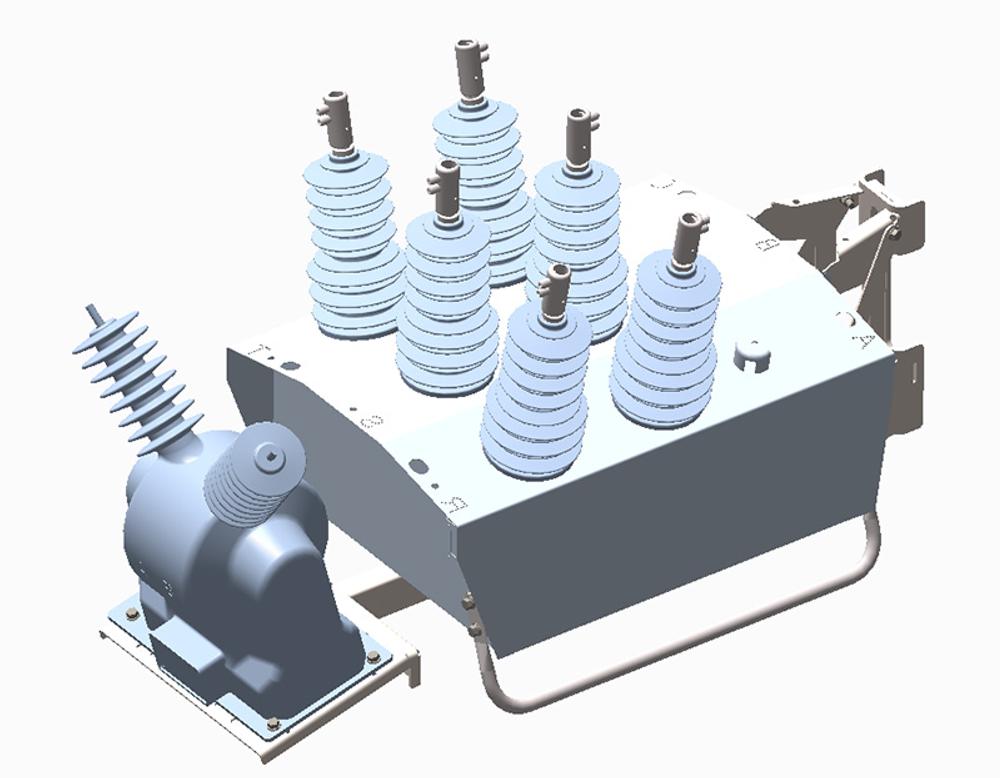

The undisputed winner in on-site construction minimisation, the combined mounting bracket allows the Recloser, surge arrestors and voltage transformer to all be built away from the pole. NOJA Power Distributors can even supply OSM Reclosers pre-kitted, so that installation is as simple as drilling two M20 holes, connecting the bolts, earths and cables. Skilled teams can complete an installation in under 2 hours on site, making it the ideal option for minimising installation costs.

Here’s an example of a NOJA Power OSM15 Recloser pre-dressed undergoing packing at NOJA Power’s Brisbane manufacturing campus. With one crate wall removed, we can see how all surge arrestors, bird guards and voltage transformer are pre-dressed in a clean workshop environment.

3. The Cantilever Voltage Transformer Bracket

The Cantilever VT installation bracket, OMB-38, is a combined assembly for mounting the VT on the far side of the OSM Recloser. This design is popular for retrofit designs, where older generation of Recloser products are replaced with NOJA Power OSMs. Some legacy installations had the Recloser on the supply side of the distribution pole, and placing the voltage transformer upstream of the supply side requires a cantilever design.

When given the opportunity, many utilities choose to update their practice to the Combined mounting bracket or the Standard Mounting bracket, both of which allow the VT to be on the supply side, but place the Recloser on the load side of the power pole.

4. The Side Mount Bracket

Sometimes, design teams need an OSM Mounting bracket that can be quickly adapted on site for varying installation requirements. For this application, the OMB-36 Universal Mounting Bracket is the choice. This side mount method uses the rails of the OSM Recloser to connect the device in place, but can provide a simplified arrangement for some overhead line arrangements. Vertical line arrangements may be best served by a side mount application like this, providing a greater phase to phase clearance for individual lines.

Conclusion

Reliable performance from overhead distribution assets is a function of product quality and installation quality – your performance is only as good as your weakest link. Having a solid understanding of the available mounting methods for the OSM Recloser provides a versatility in installation designs to build a reliable network.

“Our products have found application in 105 countries around the world and we have evolved the mounting arrangement to accommodate different pole structures in different countries,” says NOJA Power Group Managing Director Neil O'Sullivan.

For more information, visit www.nojapower.com.au or contact your local NOJA Power Distributor.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →