Technical Article

Updated 02/2025

Why Arc Fault Containment is Essential for Public Safety

Electrocution risk is well understood by the general public, but when it comes to injuries from electrical networks, electric arc burns make up a substantial portion of the casualties. On the medium voltage network, an electric arc fault can be up to four times the temperature of the surface of the sun. [1]

In fact, for a fatality, all that is necessary is general proximity to the power assets. Debilitating burns from an arc fault can occur at over 3 meters away from the fault site. [1]

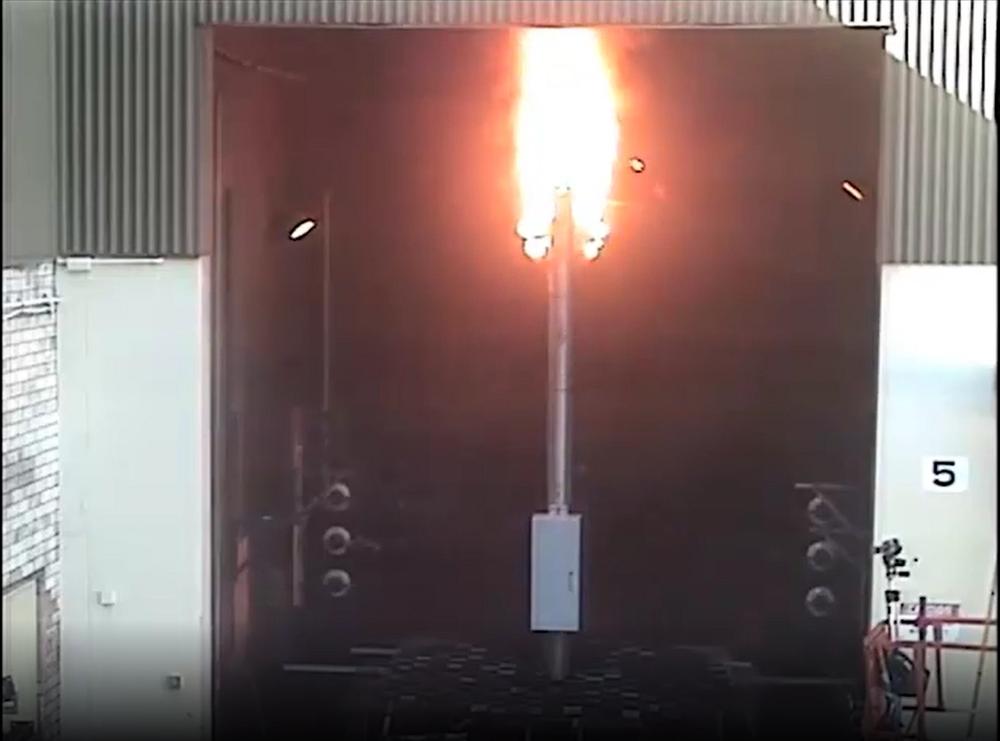

Internal arc faults in pole mount switchgear also present an explosion risk, with localized shrapnel emanating from the ruptured equipment. [2]

Whilst this risk is well known in the utility space, legacy standards often only mandate arc fault containment for indoor or ground mount equipment. However, this sentiment is derived from the distribution network of yesteryear, where areas of population density were not generally co-located with pole mounted switchgear.

The problem facing utilities today who have inherited these legacy networks is that urban population growth implies that outdoor pole mounted equipment is certainly installed in the vicinity of the general public.

Past records may not show large volumes of fatalities from pole top arc faults, but the research is clear. Unprotected humans in the presence of an arc fault will be severely injured. With population growth, as pole top assets are in more public places, people are more and more likely to be in the vicinity of these rare failures when they do occur. Therefore, mandatory arc fault control compliance is the only logical step for general public safety.

In 2019, the global evolution of standards has seen the inauguration of the first edition of arc fault containment standards for pole mount switchgear, IEC 62271-214. This is a standard derived from the - 200 standard covering general requirements for AC metal-enclosed switchgear and control gear.

Equipment which provides type tested arc fault classification provides assurance that arc faults are controlled in such a manner to mitigate the risk to operators and the general public.

For procurement engineers to demonstrate due diligence and consideration of risk to the general public, inclusion of mandatory compliance to IEC 62271-214 in specifications for pole top equipment is the sensible approach.

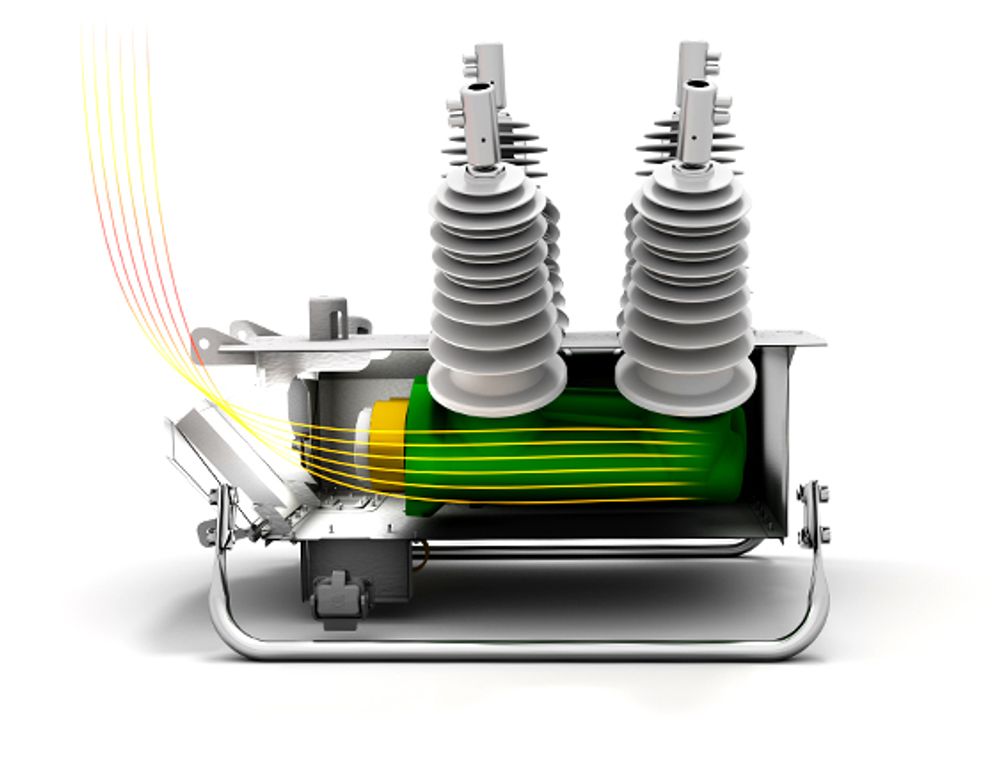

Modern pole top equipment with high safety consideration should be compliant to the IEC 62271-214 standard, with devices such as NOJA Power’s OSM Recloser demonstrating compliance to this standard in the class of solid dielectric insulated Automatic Circuit Reclosers.

“Arc Fault containment and venting has been a mandatory requirement in the development of all NOJA Power pole mounted switchgear because we understand the importance of a safety first focus,” reports NOJA Power Group Managing Director Neil O’Sullivan. “The development and release of IEC 62271-214 now provides a dedicated standard for our customers to specify to ensure they purchase switchgear to meet the highest levels of safety for their staff and the general public. The chair of this new IEEE standard development was our R&D Director David Dart. ”

[1] R. H. Lee, ‘The Other Electrical Hazard: Electric Arc Blast Burns’, IEEE Trans. Ind. Appl., vol. IA-18, no. 3, pp. 246–251, May 1982, doi: 10.1109/TIA.1982.4504068.

[2] R. Mendler, R. Hasan, J.-B. Trolle, and N. L. Mina, ‘Hazardous-Rated Electrical Equipment and the Arc-Flash Hazard’, IEEE Trans. Ind. Appl., vol. 51, no. 5, pp. 4335–4341, Sep. 2015, doi: 10.1109/TIA.2015.2424881.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →